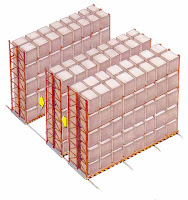

Mobile Racking System is located at the main storage area. It basically caters to slow moving and homogeneous items. Therefore, space is fully utilised in ALB, and it also reduces the time for its workers to search for exact location of the items. The vertical carousel in ALB is used to store medical supplies & items. They are stored in air-conditioned rooms as temperature & humidity control is essential. In addition, as demonstrated, units of bins are driven electronically to bring the parts to the pickers - I was astonished by the fast movement of the bins. Consequently, I learnt that thevertical carousel enables improvement in the speed and accuracy of order picking, as well as maximizes the cubic capacity utilisation in ALB.

Mobile Racking System is located at the main storage area. It basically caters to slow moving and homogeneous items. Therefore, space is fully utilised in ALB, and it also reduces the time for its workers to search for exact location of the items. The vertical carousel in ALB is used to store medical supplies & items. They are stored in air-conditioned rooms as temperature & humidity control is essential. In addition, as demonstrated, units of bins are driven electronically to bring the parts to the pickers - I was astonished by the fast movement of the bins. Consequently, I learnt that thevertical carousel enables improvement in the speed and accuracy of order picking, as well as maximizes the cubic capacity utilisation in ALB.Pallet/Bin ASRS can be found in the Autospace warehouse. Pallet ASRS is able to store up to 13500 pallets. As for Bin ASRS, it has a capacity of 2900 bins, and cranes are used to move the bins to the location at a rate of 60bins/hr. Hence, the fully computerized ASRS has maximized efficiency in the warehouse.

The Material Handling Equipment consist of the laser guided vehicle and VNA trucks. The laser guided vehicle can be found in the marshalling area, where it tracks loads with more accuracy using radio frequency, and then picks and packs the items. The VNA truck is used to assist the movement of the items in the VNA racking system where the aisle is only 2m wide.

The trip to the ALB was undoubtedly a rewarding experience as it enhanced my knowledge on the actual warehouse processes and distribution industry practices. It had provided me with an eye opening opportunity to observe how the storage systems or handling equipments were actually operated. ALB has also provided a safe and conducive environment for its workers. Moreover, ALB managed to show us the efficiency and effectiveness in its performance - the automation technology that it has adopted. Ultimately, I was really glad for the great experience!

No comments:

Post a Comment